Semiconductor Machine Robot Refurbishment

The semiconductor industry is at the heart of the technological revolution. It supplies a diverse range of electronic products that are essential to our daily lives. In this context, automation plays a key role in increasing the efficiency and precision of various manufacturing processes. However, with rapid advances in technology, the replacement of semiconductor machines with robots is becoming a major concern for companies in the sector. Here is everything you need to know about this process.

When Should a Semiconductor Machine Robot be Replaced?

Replacing a robot used in a semiconductor machine may be necessary for several key reasons directly related to the performance, reliability and compatibility of the equipment with new technologies:

- Decreased accuracy or performance: Semiconductor machine robots must maintain high levels of accuracy to handle wafers and perform various tasks without errors. Over time, mechanical wear can reduce this accuracy, thereby affecting the overall quality of production processes. A noticeable decline in performance or frequent malfunctions are therefore indicators that replacement is necessary.

- Component wear or obsolescence: Robots are subjected to intensive work cycles, which leads to natural wear and tear on parts. In addition, some components may become obsolete and unavailable on the market. This makes repairing or updating them more costly and complex than purchasing new equipment.

- Incompatibility with new technologies or processes: The semiconductor industry is evolving rapidly, constantly integrating new technologies to meet market needs. Older robots may not be compatible with modern standards or unable to adapt to requirements such as larger wafer sizes or high production speeds. In this case, replacement allows companies to remain competitive and ensure optimal productivity.

- Rising operating costs: When maintenance, repair and energy costs increase significantly, it generally becomes more cost-effective to replace the equipment.

It should be noted that by evaluating these various factors, companies can plan to replace robots at the appropriate time. This will enable them to optimise performance and reduce interruptions in their production lines.

Key Steps for the Effective Replacement of Robots in Semiconductor Machines

Replacing semiconductor machine robots requires careful planning and precise execution in order to minimise production interruptions and optimise performance. The process therefore begins with an assessment of requirements. It is important to determine the requirements of the manufacturing process and identify areas where robot replacement can bring the most benefits in terms of efficiency and quality. Once this has been done, the appropriate robots are selected. This step is essential to ensure optimal performance.

The new robots are then integrated into existing production lines. This naturally requires adequate training of personnel to use and maintain the new systems effectively. Rigorous testing must also be carried out to ensure that the new robots function correctly and meet quality and safety standards. It should also be noted that continuous optimisation is necessary to maximise performance and minimise downtime.

Replacing Semiconductor Machine Robots: Impact on Productivity and Quality

This operation obviously has a significant impact on productivity and product quality. By further automating manufacturing processes, you can enjoy numerous benefits, including improved productivity. Remember that robots are capable of performing repetitive tasks with unmatched speed and precision, allowing you to increase production throughput and reduce downtime associated with human maintenance.

They also ensure consistent precision in the execution of various tasks. This helps you reduce the risk of human error and quality variations. As a result, you will benefit from higher-quality end products and increased customer satisfaction. Programmable robots can also be quickly reconfigured to adapt to new processes or production changes. This provides operational flexibility, which is essential in a rapidly changing industrial environment.

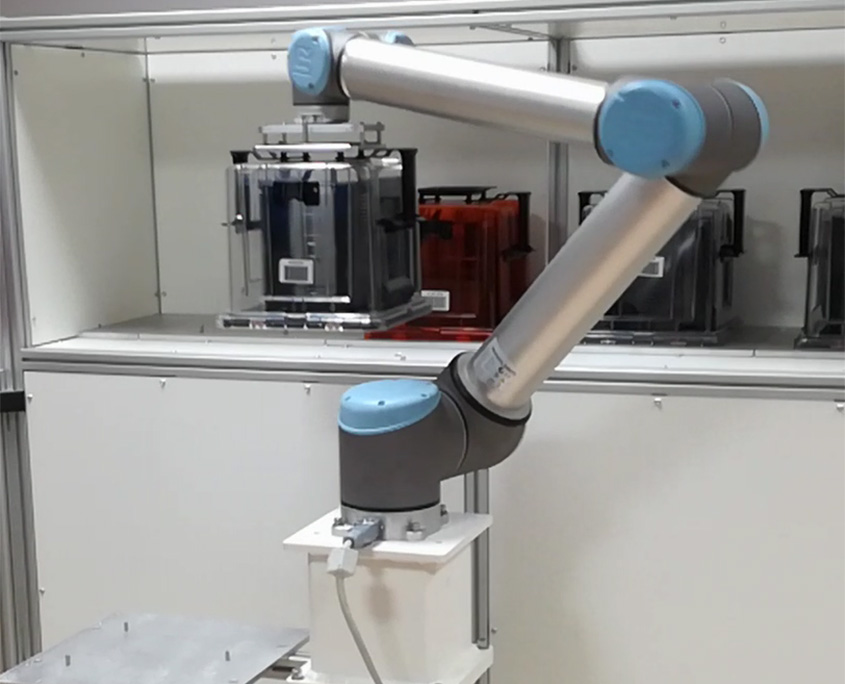

Trends and Innovations in Robot Replacement in the Semiconductor Industry with ATG Technologies

ATG Technologies is the solution of choice for semiconductor machine robot replacement. Our robot maintenance and replacement services offer tangible benefits, including advanced automation. More specifically, we offer cutting-edge robotic solutions equipped with advanced technologies such as computer vision, artificial intelligence and machine learning.

Our preventive and proactive maintenance technique also ensures continuous robot operation. This reduces unexpected downtime and optimises the availability of various equipment. We also ensure the seamless and efficient integration of new robots into existing production lines, minimising operational disruptions and enabling a smooth transition to more efficient automated systems.

In short, replacing semiconductor machines with robots is an important step towards improving the efficiency, quality and flexibility of manufacturing processes in the semiconductor industry. The key is to follow the steps mentioned above to ensure its success. In any case, with ATG Technologies, the future of robot replacement in this industry looks promising, especially thanks to our cutting-edge robotic solutions.

Would you like a quote for replacing your current systems? Contact our team of experts today, who will be happy to answer all your questions.

Get a free no obligation quote

Contact our sales team for a personalized quote.