Quality control of Wafers

We offer a standard machine which automates the control of transport boxes (Pods or Foups) or wafers themselves.

Performance and Benefits of Quality Control Systems

Improvement in workstation ergonomics and reduction of MSD risks

Reliability of handling

Improvement in the traceability of the process

Decrease in particulate inputs

Different Applications

Case 1: Inspection Systems for Foups

Benefits of a FOUP Inspection System

The use of a FOUP inspection system delivers many benefits to any semiconductor fab, such as:

- Implement a more complete and quicker FOUP control process

- Ensure that wafers are processed in Fit For Use FOUPs.

- Add new defect detection thru a quick setup process

- Integrate easily new FOUP types in Manufacturing process

Applications for Foup Inspection Systems

A FOUP inspection system can include the following applications:

- Identify FOUP Type and FOUP/Door Adequacy

- Inspecting transport Mushroom integrity

- Inspecting door opening system integrity

- Inspecting purge port integrity

- Checking FOUP slots and door integrity

- Checking physical contamination absence

Versatile equipment allowing adding new defect inspection upon request.

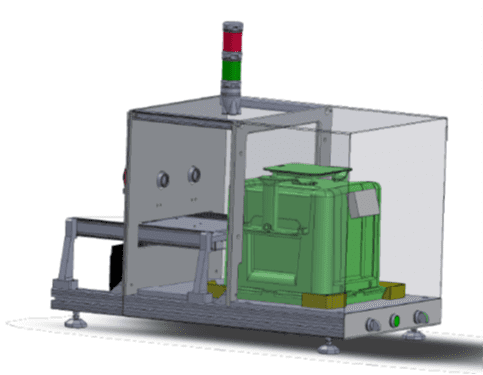

Case 2: Pod Quality control

Since the pods and baskets are in contact with the wafer throughout the process, it is absolutely necessary to check their physical integrity before returning them to the manufacturing process.

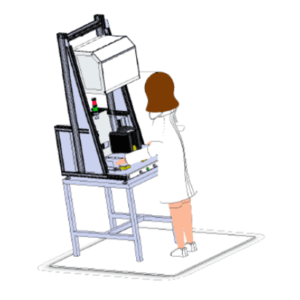

Fixed table system to control both foups or pods.

Fixed table system to control both foups or pods.

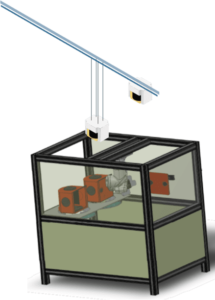

Case 3: Wafer Quality control

As the wafers are in contact with the wafer throughout the process, it is absolutely necessary to control their physical integrity before sending them back to the manufacturing process.

- OHT powered system

- The robot opens the Foup and places the door on its inspection support

- Due to the complexity of the inspection, the camera is mounted on the robot arm

- The movements of the robot are synchronized with rotating load ports to ensure all faces are accessible.

Get a Custom Quote for a Quality Control System

Contact our sales team to get a custom quote or documentation for an ATG Technologies quality control system for foups or pods.