Automated Loading of Tools and Intra-bay Transport (OHT)

In the semiconductor industry, the transport of batches from one location to another requires an efficient and tailor-made transport solution. This serves to reduce cycle time, lower production costs and make the production process more profitable.

For automated tool loading and intra-bay transportation (OHT), choose the solutions offered by ATG Technologies.

Automated Tool Loading and Intra-Bay Transport (OHT)

The performance of a semiconductor production line depends on many factors. In addition to the configuration, layout and layout constraints of the machines, there is also the type of batch loading and transport system. The Automated Material Handling System (AMHS) is a transport order executor operating at the heart of the production line’s internal supply chain. It is controlled by the Manufacturing Execution System (MES), the originator, and by the Execution Control System (ECS), the information manager.

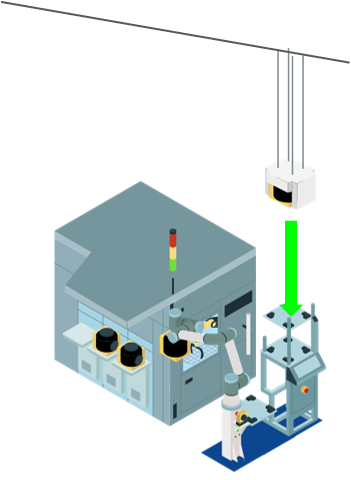

Among the most widely used AMHS solutions is the OverHead Hoist Transport (OHT). They usually operate from the ceiling and are guided by rails. Their deployment optimises the management of floor space occupied by machines and operators.

The role of the tool loading and intrabay transport system is to load the OHTs into batches and to transport and store them. Batch transport is managed by zone, also called “bays”. Each bay has its own control unit whose role is to manage transport requests. The control units share information on the number of pending transport requests, the number of OHTs available in the bay and the number of OHTs required to fulfil these requests. The role of the control unit is to meet the transport needs in the bay taking into account the available transport resources. If there is a shortage of OHTs in the area, for example, it calls up the excess OHTs in other areas. On the other hand, if there is an excess of OHTs in the bay, the unit sends them to other bays.

Overhead hoist systems (OHTs) require ceiling mounted rails. They are electrically powered by cable. This avoids the problems of battery replacement that are common with AGV systems. They are loaded in batches by means of mechanical arms. They can only accommodate one batch at a time. A batch consists of between 1 and 25 semiconductor wafers.

An automated tool loading and intra-bay transport (OHT) has many advantages, including:

- Optimisation of competitiveness: the overhead hoist transport system is faster and more reliable (reduction in production cost);

- Maintaining the integrity of the wafers, as they are no longer transported manually;

- Optimisation of the working conditions of the operators by reducing the risks of musculoskeletal disorders.

ATG Technologies, a Passion for Technology

Trust ATG Technologies, your designer and integrator of automated tool loading and intra-bay transport (OHT) systems. We offer you sophisticated wafer loading and transport systems incorporating the latest innovations. Thanks to our collaboration with Focussia, a Montpellier-based company specialising in the computerised design of communication protocols, we are able to provide you with high-performance, innovative and communicating wafer transport systems (OHT). All our solutions are designed to fit your production site configuration and your production needs.

For more information, please contact our technical experts via our contact form here.

Get a free no obligation quote

Contact our sales team for a personalized quote.